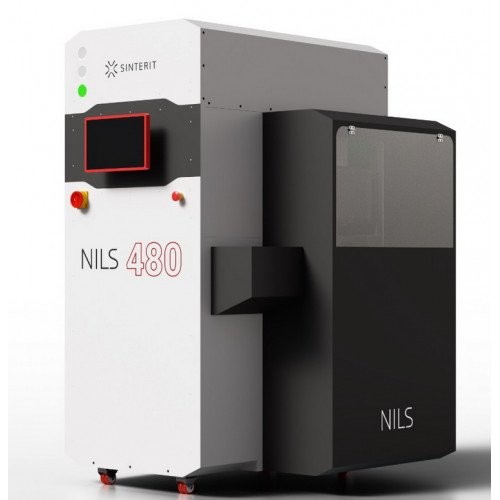

The Sinterit NILS 480 is a professional industrial-grade SLS 3D printer that features reinvented productivity to ensure the best return on investment on the modern SLS technology market.

With NILS standing for New Industrial Laser Sintering, the extent of automation, performance, maintenance, machine speed, and other features have been upgraded to streamline the workflow and deliver accurate results. The large build chamber allows printing objects of up to 480 mm in diameter — not only models and prototypes but also functional products and parts. The powerful laser and the galvo scanning system make for lightning-fast printing without compromising the quality of outputs. This model is also equipped with automated systems for powder distribution and continuous printing, which further increases the ergonomics of the machine.

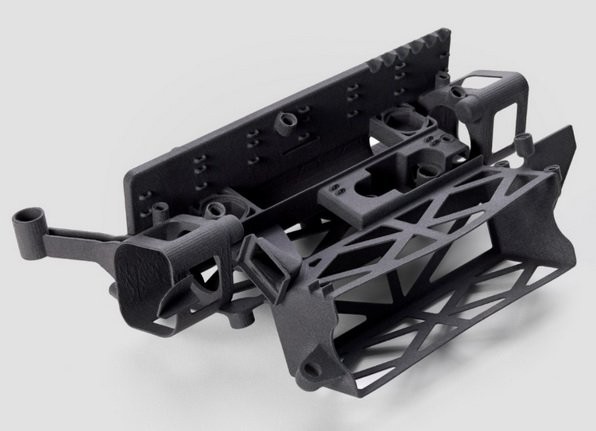

The Sinterit NILS 480 can be used in a great many industries, the applications for this printer being virtually unlimited. For example, it can print large medical models, orthoses, automotive prototypes, housing for electronic devices, single-piece shoes, and a wide range of parts for different purposes.

Look through the following table to compare the specs of the Lisa X with other products by Sinterit.

|

Parameter |

Lisa |

Lisa PRO |

Lisa X |

NILS 480 |

|

Build volume |

110 x 160 x 155 mm

4.3 x 6.3 x 6.1 in |

110 x 160 x 245 mm

4.3 x 6.3 x 9.6 in |

130 x 180 x 330 mm

5.1 x 7.1 x 13.0 in |

200 x 200 x 330 mm

7.9 x 7.9 x 13.0 in |

|

Max. print diagonal |

248 mm

9.8 in |

313 mm

12.3 in |

398 mm

15.7 in |

435 mm

17.1 in |

|

Print speed |

3 mm/h |

3 mm/h |

10-14 mm/h |

10-14 mm/h |

|

Laser type |

IR 5 W |

IR 5 W |

IR 30 W |

IR 30 W |

|

Wavelength |

808 nm |

808 nm |

976 nm |

976 nm |

|

Layer height |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

0.075–0.175 mm

0.003–0.006 in |

|

Scanning type |

XY |

XY |

Galvo |

Galvo |

|

Laser spot size |

400 μm

0.0157 in |

400 μm

0.0157 in |

650 μm

0.0256 in |

560 μm

0.0220 in |

|

Feed bed capacity |

3.4 L |

5.2 L |

14 L |

30 L |

|

Inert gas control system |

- |

✔ |

✔ |

✔ |

|

Automatic Powder Distribution System (APDS) |

- |

- |

- |

✔ |

|

Continuous Printing System (CPS) |

- |

- |

- |

✔ |

|

Outer dimensions |

620 x 400 x 660 mm

24.4 x 15.8 x 26.0 in |

690 x 500 x 880 mm

27 x 20 x 35 in |

650 x 610 x 1200 mm

25.6 x 24.0 x 47.2 in |

1200 x 1200 x 1750 mm

31.5 x 47 x 69 in |

|

Weight |

44.0 kg

96.8 lbs |

90 kg

198 lbs |

145 kg

330 lbs |

300 kg

660 lbs |

|

Display |

4" interactive touchscreen |

7" interactive touchscreen |

9" interactive touchscreen |

15.6" interactive touchscreen |

|

Software |

Sinterit Studio |

Sinterit Studio |

Sinterit Studio |

Sinterit Studio 2 |

|

Connectivity |

WiFi, USB |

WiFi, USB |

Ethernet, WiFi, USB |

Ethernet, WiFi, USB |

The Sinterit NILS 480 is an SLS 3D printer that can print layers at 75 microns. This way you can produce parts with smooth exterior surfaces. The high-precision and sturdy hardware coupled with a responsive, performance slicer can deliver movable parts with complex geometry and provide high dimensional stability.

|

NILS 480 |

LISA X |

LISA PRO |

LISA |

|

|

Standard |

||||

|

PA12 Smooth 2/6 kg |

✔ |

✔ |

✔ |

✔ |

|

PA11 Onyx 2/6 kg |

✔ |

✔ |

✔ |

|

|

Performance |

||||

|

PA11 CF 2/6 kg |

✔ |

✔ |

✔ |

|

|

PA11 ESD 2/6 kg |

On demand |

✔ |

✔ |

|

|

PP 6 kg |

On demand |

✔ |

✔ |

|

|

Flexible |

||||

|

TPE 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Bright 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Soft 2 kg |

On demand |

✔ |

✔ |

|

|

Flexa Grey 2/6 kg |

✔ |

✔ |

✔ |

✔ |

Sinterit offers a wide range of proprietary materials covering the majority of industrial needs. These consumables feature strength, dimensional stability, impact and temperature resistance. Also, it is possible to modify the existing profiles included in the software as well as use materials from other providers.

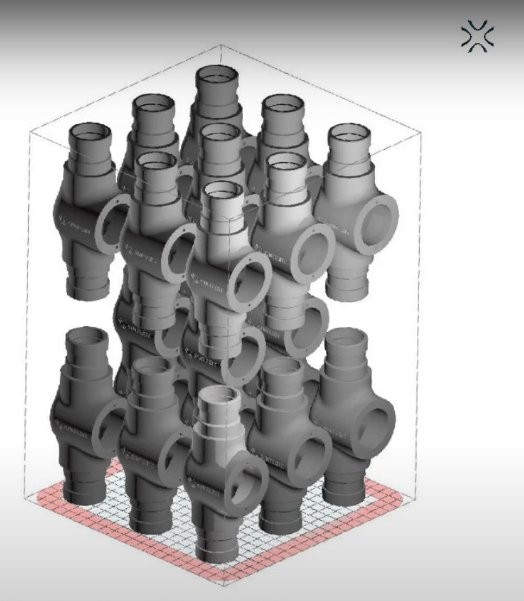

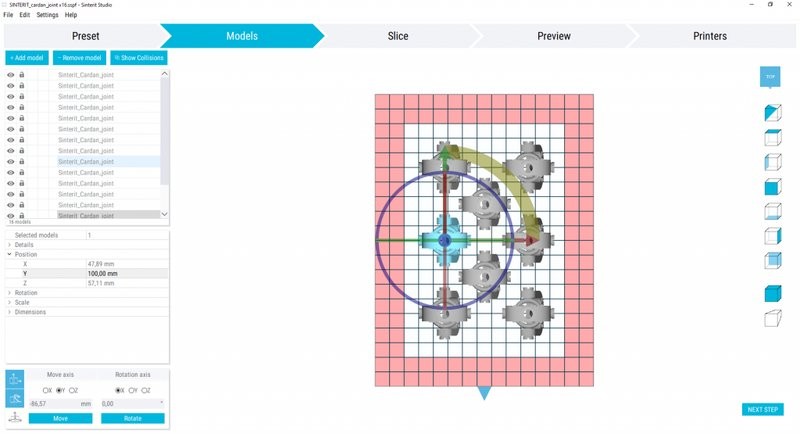

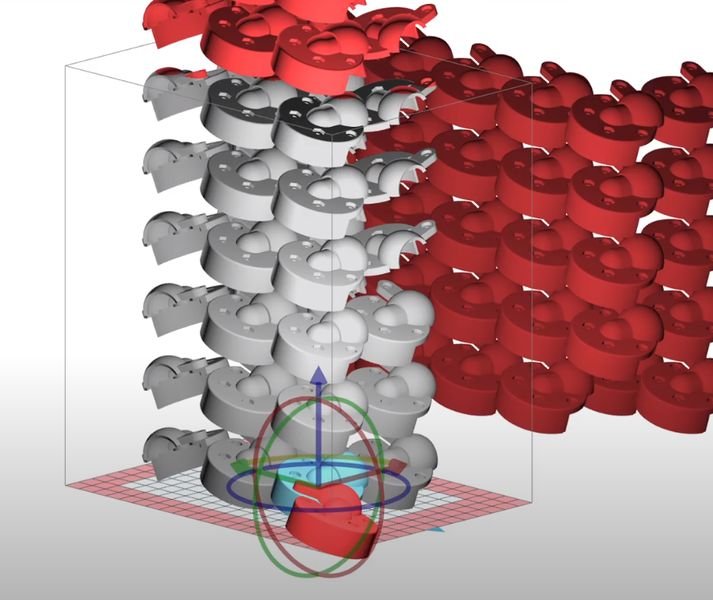

The build area of 7.9 x 7.9 x 13.0 inches (200 x 200 x 330 mm) lets you print one large model or a multitude of small workpieces in a single session. Coupled with the print speed of 14 mm/h, this makes it possible to produce, for instance, 22 air valves in less than 18 hours.

The NILS 480 can be controlled via PC or its large 15.6-inch interactive touchscreen that features intuitive navigation allowing you to manage the printing process with ease from the very first use.

The printer boasts several connectivity options for printing 3D models: USB, LAN, and Wi-Fi.

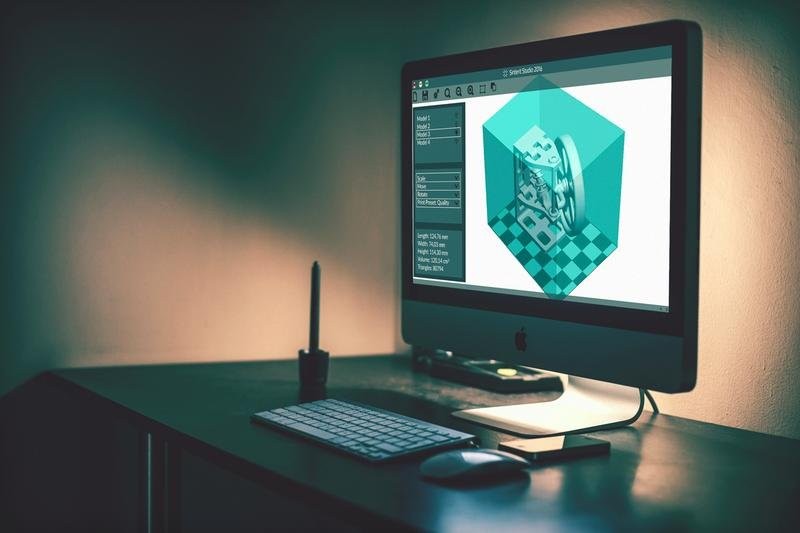

The device comes with a renewed version of the efficient proprietary software called Sinterit Studio 2 that features enhanced user experience and increased automation. With a multitude of parameters to control, users can adjust laser power, laser movement, printing temperature, warmup and cooldown, model scale, and other options like shell printing. The software works with 3D models in a variety of common 3D formats. It is available for Windows 10 and above.

The unique Auto Nesting solution built into the software ensures the optimal arrangement of parts to be printed.

For some items, package content may change. In case of any questions, please get in touch.

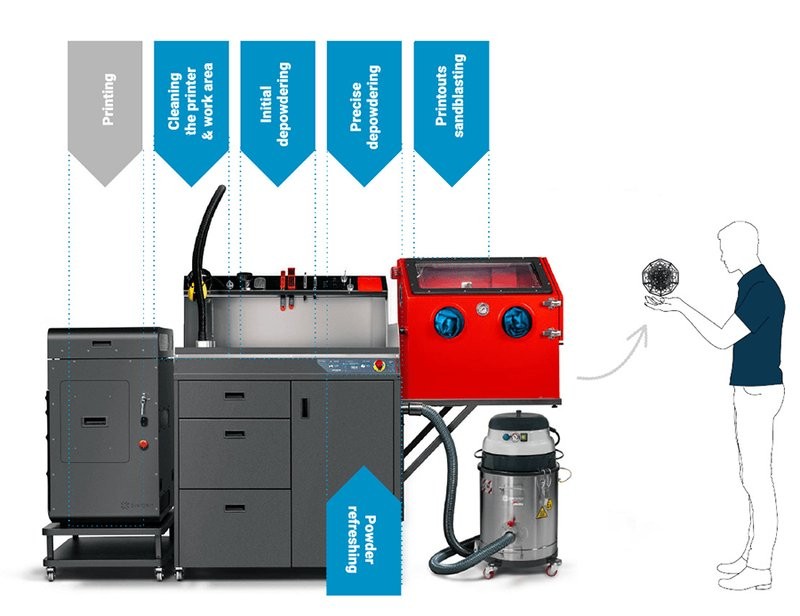

Apart from the basic set, Sinterit offers peripheral equipment (purchased separately as add-ons or as a complete set with the printer) to enhance operation and user experience. This includes:

The Sinterit NILS 480 is available in white with black and red trimmings. Its stylish look will decorate any type of workshop.

The printer dimensions are 47.2 x 47.2 x 68.9 inches (1200 x 1200 x 1750 mm). It weighs 550 lb (250 kg).

To learn the current price of the Sinterit NILS 480, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now